Jim's Homemade Bubble Machine

Made this bubble machine a few years back for the kids.

Parts

- 1/16" Acrylic, approximately 2' x 2'.

- Weldon-3 Acrylic Glue

- Low RPM 12V motor (I used a 20rpm gearhead motor.

This one

from All Electronics, $13.75, might work. Also check that site for other gearhead motors.)

- Two 100 Ohm Potentiometers

- SPST Toggle Switch

- 12V DC 92mm Muffin Fan (Like this one

from All Electronics, $3.50)

- 8-Cell AA battery holder (Like

Radio Shack #270-407, $1.89)

- Bubble Solution (available at Kmart, target etc. You can usually find half gallon or bigger

jugs for a couple bucks)

- (Optional) Fuse Holder with 0.5A fuse

- (Optional) Female coax power jack with switch

like

this

or

this

depending on the plug on your wall transformer.

- (Optional) 12V wall transformer

- (Optional) Several blinking LEDs

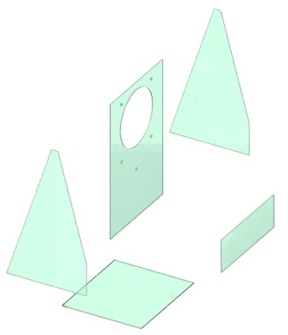

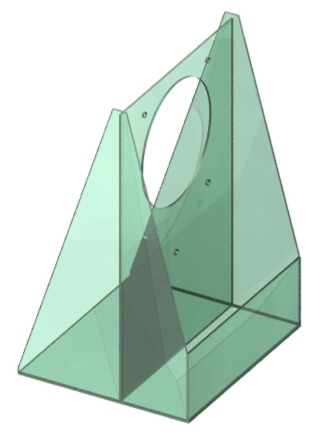

Scale Drawings for Apparatus

The main support. You may need to resize the various holes to match your motor and fan.

The sides.

The bottom and front.

The bubble wand was constructed from 1/16" acrylic as outlined below.

- Drill 16 3/4" holes where indicated in the drawing below.

(The red dashed layout rings are

at 1.25, 1.5" and 2" diameters.)

- Drill 16 3/32" holes.

- Drill a suitable hole for the motor axle.

- Cut along the heavy doted red line with a scroll saw.

- I added a circular piece of acrylic to the center so there was more material in contact

with the motor axle.

- The bubble wand was epoxied to the mtor axle.

Wiring Diagrams

Simple Circuit

More compex circuit

This more complex circuit includes speed controls for the fan and wand motor

and a simple recharging circuit. I used a 0.5 amp fuse.

Construction

If you look closely at the scale drawings you'll notice that the main support and the

bottom are supposed to be the same width. It is critical that this is so. If these are not the same width

it will be very difficult to get the bubble solution compartment to seal. I first cut a piece of acrylic that

was 5-3/4" wide and about 15" long. From this piece the main support and bottom were cut. The exact

dimensions of the side and front pieces are less critical.

The acrylic parts were cut out and the various holes were cut or drilled. The pieces were then

taped and clamped together and the Weldon 3 glued applied with a syringe. The glue is just drawn into the

joints by capilary action. My parts were cut accurate enough so that the joints were water tight.

If your joints leak, you can use bath tube caulk to seal them.

The electronics were now installed. I got a bit carried away and included blinking LEDs, motor speed

controls and a recharging circuit. All you really need is the fan, motor, battery holder and a switch.

If you include the ability to use a wall transformer then you should include the 0.5 amp fuse for safety.

Making Bubbles

Just fill the resevoir up with bubble solution and turn it on.

Recharging

Make sure the polarity matches your wiring!

Just plug in a 12V wall transformer for a few hours.

Copyright ©2005 J. Sluka

Last Modified: 15 August 2005

Send me an email