Ever bought a part because it was cheap and you figured there had to be something interesting you could do with it? Well, that's where this comes from. I bought the valve more than a year ago from here for $4.50. It is a 3/8" solenoid operated diaphram valve. Apparently it is the water control valve from a washing machine. It is too small for your typical 1.5" or 2" barrel spud gun.

|

24 Vac solenoid valve. Inlet valve has 3/4" male thread and has a filter screen. Mounting flanges on both sides of inlet with screw slots on 1.5" centers. Metal outlet valve with 1/2" male pipe thread. Includes a compression nut with 0.53" hole and rubber bushing. Plastic solenoid body, inlet valve and diaphragm housing. 0.25" qc solder terminals on solenoid. |

After laying in my parts box for months I figured out that it should work great for a 1/4" barrel ... hence a BB gun. I figured I would make a single shot BB gun with it but it turns out it works very well as a BBMG.

It is pretty simple, and needs a stock, grip etc.

The inlet is a 3/4" Sch40

PVC female thread adaptor, a 3/4" plug and

a 3/8" quick connect. The quick connect is "ghetto tapped" into a 1/2"D

hole in the plug. The valve inlet is 3/4" GHT (garden hose thread, not

NPT), made of plastic, and is a perfect match to the threaded 3/4" PVC

coupler.

The outlet is a 1/2" Sch40 PVC

female thread adaptor, a 1/2" plug with a hole in it (to keep the BBs

from rolling back into the valve) and a

1/4" compression to 1/8" NPT coupler. The coupler is ghetto tapped into

a 3/8"D hole in the plug. The outlet of the valve is actually for a

compression fitting so the threads are not NPT. But the diameter and

thread pitch matches the 1/2" threaded PVC coupler so it fits very

well. It does need several turns of teflon tape for a real good seal. I

wanted to be able to get into the BB resevoir for future modifications

so the plug is held in place with three screws.

The barrel is 36" of 1/4" brake line.

Loading is pretty high tech -- you roll a bunch of BBs into the barrel. To keep the BBs from roling back out of the barrel I stick a magnet to the barrel just in front of the brass fitting. This is how I had planned to make it a single shot gun, roll a single BB into the barrel and let the magnet keep it out of the valve.

Currently, the trigger system is, well... on the back side of the valve are two spade plugs with the same separation as the contacts on a 9 volt battery, so I just touch the battery to the contacts and off it goes.

The valve works very well for this application. It dumps a ton of air and the gun recoils a lot from the air pressure alone. Much more so than my vortex gun.

Not sure how many BBs it will actually hold, I've been using sets of

50 for testing. A rough calculation suggest about 150 might fit.

There really isn't a "chambering" mechanism ala a cloud or vortex BBMG.

Just a bunch of air flowing through it.

My homemade chrono gave the following (averages from several relatively short bursts at 120 PSI) --

I wonder if extending the outlet with a piece of PVC pipe, or adding

a T, would boost the BB capcacity.

It is surprisingly efficient at firing all the BBs in the outlet

coupler, unlike a cloud or vertex design that usually doesn't want to

fire the last couple of BBs.

| WARNING: I've noticed a tendency for the valve to open briefly when you first connect the air supply line. It doesn't do it every time, only occasionaly. POINT IN A SAFE DIRECTION WHEN CONNECTING THE AIR LINE. |

My gun using this breech design consistently fires two BB's for each trigger pull (I use a small diaphram valve instead of a blowgun). I use a very strong capture magnet so I don't think the problem is that the magnet is too weak. Instead, I believe the magnet is too strong.

With a strong enough magnet another BB gets sucked into the barrel by the magnet before the selector piston has time to move. Try firing your gun without the capture magnet (keep the muzzle pointing up so the BBs don't all roll out the barrel). Omitting the magnet completely might give you an idea as to whether the magnet is too strong or too weak.

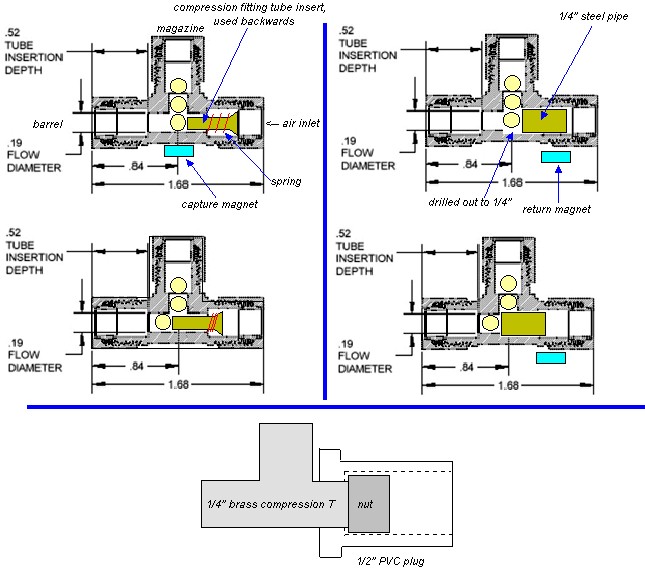

BillyBoB... the selector is just a tube insert, the little flared piece of copper tubing that comes with the fitting for use with plastic hose. It is just installed backwards. It may need to be shortend slightly.

The original design is on the left above. A modified untested design (on the right) uses a steel tube as the selector and magnetic return. I was thinking the steel tube would just be a short length of 1/4" brakeline slightly crimped on the muzzle end to keep BBs out of it.

My current design

The toroidal magnet, acting on the steel washers, returns the selector to its starting position. This design also tends to fire two BBs for each pull of the trigger.

If you take a look at my post BBMG With a Diaphram Valve shows the basic design but the 1/4" compression coupler is replaced by the compression T.

Draculon: Great measurement! Always nice to have some real data. How long was the barrel? Pretty well matches my calculations.

Using the chrono results for my vortex type BBMG I've calculated the effective pressure for my gun. I've also calculated what the muzzle velocity would be if I really could get 120 PSI pushing the BBs. Some numbers for my vortex BBMG;

muzzle velocity = 330fps

barrel length = 3'

mass of a BB = 0.37g (calculated from diameter of BB and density of iron)

pump outlet pressure = 120PSI

The acceleration is;

Accel = (muzzle velocity)/(time in barrel)

I estimate the "time in barrel" assuming the average velocity in the barrel is half the muzzle velocity (330fps/2), so

Time in barrel = 2*(barrel length)/(muzzle velocity)

= (2*3')/(330fps)

= 0.0182 seconds

and the acceleration is;

Accel = (muzzle velocity)2/(2*barrel length)

= (330fps)2/(2*3')

= 18,150'/s2

Now, if I remember basic physics, to calculate the acceleration of the BB assuming 120PSI pushing it and no friction,

Force = (Mass)(Accel) = (Pressure)(Area)

Accel = (Pressure)(Area)/Mass

120PSI= 8.3x105N/m2 (convert to MKS units)

Accel = (8.3x105Kg/ms2)(0.159cm2)(m2/1002cm2)/(0.37x10-3Kg) (0.159cm2 = BB cross sectional area)

= 35,668 m/s2

Converting meters to feet;

(35,675 m/s2)(3.28feet/meter) = 117,000ft/s2 (that's 3,656 Gs!)

Converting from acceleration to muzzle velocity;

muzzle velocity = sqrt(2(Accel)(barrel length)))

= 838 fps for 117,000ft/s2 and a 3' barrel

My BBMG actually gives an average muzzle velocity of 330 fps.

From 330 fps you can back calculate what the effective pressure in the chamber is ... I get an effective pressure of 18.6 PSI from a pump outlet pressure of 120 PSI. (Draculon measured 18 PSI chamber pressure for a 100 PSI inlet pressure in a smallish chamber cloud gun.)