Continuing on with interesting things that can be learned with a closed combustion chamber burning propane and air, we will see if it is possible to measure the temperature of the combustion gases as the chamber is fired.

To measure the temperature we will examine the acoustics of the

chamber. An air filled pipe, closed at both ends, resonates at a

predictable

frequency. This resonant frequency is a function of the

length of the pipe, whether or not the ends are closed, and the

temperature of the air in the pipe.

Our data set will be the piezo transducer signal measurement from

the combustion of stoichiometric propane in air in a closed combustion

chamber.

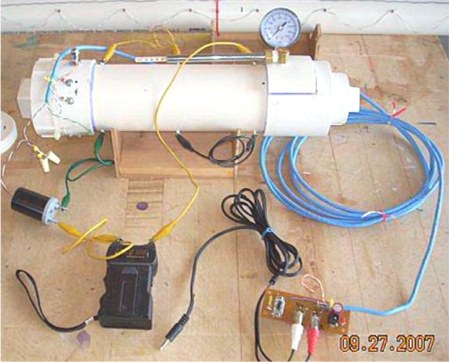

The measurements were made with the chamber fan running and three spark gaps. For more details see my closed chamber page and the build log page.

An air filled pipe closed at both ends resonates at a frequency

given by;

f =

nv / 2L (Eq.

1)

Where;

f

is the frequency

n is an integer (1 = fundamental, >1

for overtones)

v

is the speed of sound

L is the length of the pipe.

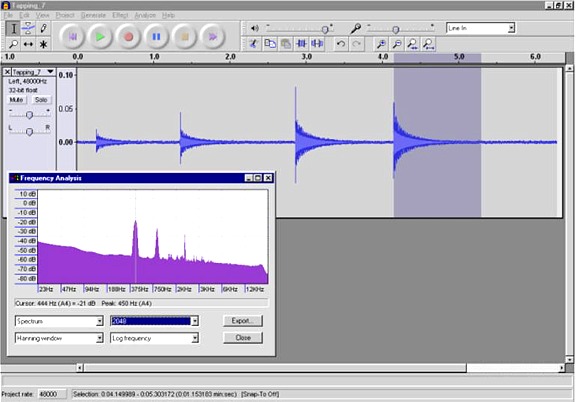

The combustion chamber does not have nice flat ends. Both

ends are

capped with threaded plugs which give complex shapes at the ends of the

pipe. Therefore, instead of attempting to measure the length of the

chamber directly, I smacked the end of the chamber with a hammer and

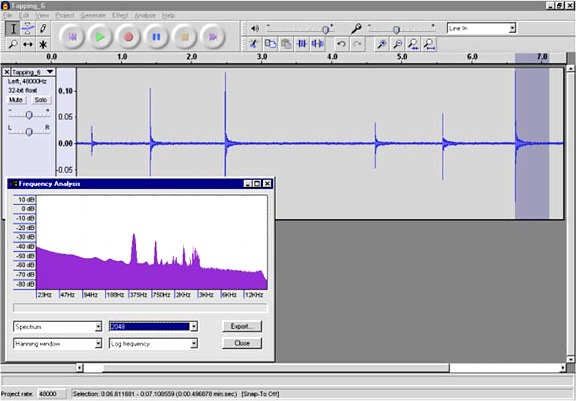

recorded the audio signal produced by the piezo transducer. Below is a

screen shot of the Audacity window showing several smacks. The inlay is

a spectrum analysis of the last smack (the highlighted region). Under

these conditions the chamber resonated at a frequency of 440Hz.

Here is a wav file of the

last tap.

I also pressurized the chamber to ~100 PSIG and recorded the tapping. (The speed of sound is independent of the pressure.) The pressurized chamber resonates at about the same frequency, 450 Hz this time, but with much better tonal quality.

Here is a wav file of the

last tap. The sound recorded by the piezo transducer sounds pretty

good, similar to a bell being rung. Note that the wav file is not what it sounds like to

me as I smack the chamber. To me it just sounds like a hammer striking

a hunk of PVC. Inside the chamber is the only place where the bell like

sound can be heard since there are no openings in the chamber. For the

same reason the chamber makes very little noise when fired, it makes

very little noise on the outside when struck.

The

temperature in my "lab" while doing this was 45F (7.2C). The speed of

sound in air at this temperature was calculated with

the commonly

used equation;

vt

= v0(sqrt(1+ Tc/273.15))

(Eq. 2)

Where;

Tc is the temperature in

degrees celsius

v0 is the speed of

sound in dry air at 0C, 331.4m/s

vt is the speed of

sound at temperature Tc in m/s

Using Tc of 7.2C we get vt = 335.7m/s (1101.5FPS).

Using the resonant frequency of the chamber and the speed of sound

at this temperature,

we can calculate an "acoustic length" for the chamber by solving

equation 1 for L.

L =

nv / 2f

Plugging in v=1101.5FPS, f=450Hz and n=1 gives an

"acoustic length" for the chamber of 1.224 feet (14.7 inch). The actual

overall length of the chamber is 15 inches.

The speed of sound in the combustion products for propane in air was calculated using GasEq. Starting with propane in air at a temperature of 10C (50F) the peak combustion temperature was calculated using GasEq's "Adiabatic T and composition at defined V" calculation. The change in the speed of sound (vsound) in the combustion products was then calculated using GasEq's "Equilibrium at defined T and constant V" calculation as the temperature was lowered in seven steps to 500K (227C). The vsound was plotted versus the celsius temperature (Tc) in Excel and fit with a fourth order polynomial. The resulting equation is;

Tc = (-6.497x10-8)vsound3 + (6.886x10-4)vsound2 - (0.9200)vsound + 3076, R2 = 1.000 (Eq 3)

Where;

Tc is the gas temperature in

degrees celsius

vsound is the speed

of sound in FPS.

Equation 3 allows us to calculate the temperature of the gases from

the speed of sound in the gases.

We are now ready to calculate the temperature of the combustion

gases based on the recording of the piezo transducer's signal during

firing of the chamber.

To estimate the temperature in the chamber at various times I took

windows of the piezo recording ten cycles wide and measured the time.

The average

frequency within the window is f = 10/(window

width in seconds). The time at the center of the window was used as the

time for the particular measurement. From the frequency, and the

acoustic length of the chamber, the speed of sound within the chamber

can be calculated with equation 1 after solving for the speed of sound (v);

v

= 2f

L / n

Where the variables are as defined before. n is assumed to be 1, L

is 1.224 feet (the chamber's acoustic length) and f is the frequency measured within

the 10 cycle windows.

v

= (2)(1.224ft)f

v = (2.448ft)f

From the speed of sound in the chamber the temperature of the

gases can be calculated using the GasEq derived values using equation 3.

The graph below shows a region of the piezo transducer recording.

The left side of the graph corresponds to the maximum piezo signal. The

10 cycle boxes are outlined in red. The values for each box are the

observed frequency, the time to the center of the box, the calculated

speed of sound (v) in FPS and

the calculated temperature in degrees Celsius. In the vicinity of the

peak piezo signal the signal is too complex to measure the frequency,

the earliest frequency I could measure was at 32.8mS after ignition,

about 8mS after

the peak piezo signal.

According to GasEq, the peak adiabatic temperature for the

combustion of

propane in air with a starting temperature of 10C is 2358C. The maximum

observed temperature, based on the chamber's acoustics, was 2061C.

Since this value was measured 8mS after the peak piezo signal it

probably is a bit lower than the actual peak temperature in the chamber.

The time versus temperature data from the graph above, along with a

few additional time points, is summarized in the table below.

| Time

From Ignition (mS) |

Time

From Piezo Max (mS) |

Frequency (Hz) |

Speed

of Sound (FPS) |

Temperature (C) |

| 32.8 |

7.8 |

1244 |

3048 |

2061 |

| 41.0 |

16.0 |

1209 |

2962 |

1936 |

| 49.4 |

24.4 |

1183 |

2898 |

1844 |

| 57.9 |

32.9 |

1156 |

2832 |

1750 |

| 66.7 |

41.7 |

1122 |

2749 |

1632 |

| 78.0 |

53.0 |

1113 |

2727 |

1602 |

| 104.2 |

79.2 |

1056 |

2587 |

1412 |

Below is a graph of the calculated temperature versus time from ignition. Extrapolating the temperature to the piezo peak time (marked with the red line) indicates a temperature of 2200C at the time when the piezo signal was maximum.

The temperature appears to drop very quickly. For the seven

measurements shown in the table the temperature appears to drop 649C in

just 71 milliseconds. Based on the time and temperature drop we

can estimate a thermal half-life of this chamber of about 110mS. So,

for

every 110mS after the temperature maximum the temperature drops by a

factor of two. For example, at 355mS after ignition (three t1/2's

plus 25mS from ignition to the piezo's maximum signal), the temperature

in the chamber will have dropped by about 88%.

We can use the Ideal Gas Law to relate the temperature in the

chamber to the pressure in the chamber;

PV = nRT

Since the volume (V), number of moles of gas (n) and the gas law

constant (R) are all constants for the closed chamber once combustion

is complete, we can simplify the gas law to;

P = kT

Where k is a proportionality constant. Therefore the pressure in the

chamber is proportional to the temperature in the chamber and the

pressure drops at the same rate as the temperature. So, within a couple

of tenths of seconds after combustion is complete the pressure in the

chamber will have dropped back to near atmospheric pressure.

Since the energy in the chamber is proportional to the

temperature of the gases, the energy in the chamber drops at the same

rate. Within a couple tenths

of

a second after ignition virtually all of the energy in the chamber has

been lost as heat transferred to the chamber walls.

The calculations above were done using the combustion recording

obtained with

the chamber's fan running. To see if the fan makes a significant

difference in

the rate of heat loss I have applied the same analysis to a recording

of the chamber fired with the fan off. The fuel was injected, the fan

was

run for a minute or so, the fan was then turned off and the chamber

left to sit for 5 minutes (to allow the gases to stop moving) and then

fired. For this firing only the central spark gap was used.

The table and graph below gives the acoustically calculated

temperature

versus time plot for this second set of data.

| Time

From Ignition (mS) |

Time

From Piezo Max (mS) |

Frequency (Hz) |

Speed

of Sound (FPS) |

Temperature (C) |

| 43.60 | 4.76 | 1203.4 | 3057 | 2074 |

| 51.75 | 12.92 | 1250.0 | 3175 | 2249 |

| 59.91 | 21.08 | 1203.4 | 3057 | 2074 |

| 68.29 | 29.46 | 1182.0 | 3002 | 1994 |

| 76.80 | 37.97 | 1168.2 | 2967 | 1943 |

| 85.46 | 46.63 | 1142.9 | 2903 | 1850 |

| 94.29 | 55.46 | 1121.1 | 2848 | 1771 |

| 103.37 | 64.54 | 1083.4 | 2752 | 1637 |

| 112.74 | 73.91 | 1051.5 | 2671 | 1525 |

| 130.50 | 91.67 | 1035.2 | 2629 | 1468 |

| 140.21 | 101.38 | 1025.6 | 2605 | 1436 |

| 150.06 | 111.23 | 1004.0 | 2550 | 1362 |

The chamber burns slower without the fan running and with a single

spark, the piezo's

maximum signal occurring 39mSec after ignition versus 25mSec for

combustion with the fan running and three sparks.

The estimated t1/2

for heat loss without the fan running is 114mS, essentially identical

to the 110mS measured for the chamber with the fan running. (For more

information on the closed chamber combustion studies see my Closed Chamber

Studies age.)

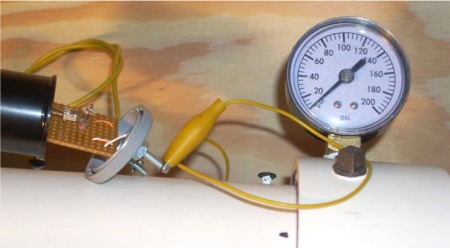

To confirm the above results, and to further examine the temperature

and pressure drop I have used a

digital still camera's video mode to record the movement of the

pressure

gauge's needle during firing.

For this chamber firing the tire pressure gauge was removed since

that gauge tends to leak. A leak test of the chamber indicated that the

leak rate was about 1 PSIG per minute at 100 PSIG. The chamber fan was

not running for this firing, though it was used to mix the gases.

The spark detector was pulled out of it's case (on the left side of

the photo) in the hope that the

video would record the ignition spark. Unfortunately, either the spark

is to

dim, or lasts for too short a time, to be recorded by the camera. The

data recordings for this spark setup give a spark duration is only

about 50 uSec, roughly 1/700th the video frame rate.

The gauge's response was recordable and the movie file is here.

The image below shows 32 video frames recorded during the firing of the

chamber. The camera's nominal frame rate is 30 FPS (one frame every

33.3mSec). In the first two frames the gauge's needle hasn't moved. In

the third frame the needle is a blur in the range of 80 to 100 PSIG. In

the next frame the needle is less blurry and the pressure has already

dropped to about 76 PSIG. Over the next 24 frames (0.8 seconds)

the needle is sharp in the images and drops down to 8 PSIG, which is

the minimum reading of this gauge.

The peak pressure in the chamber is difficult to determine from the

video. The blurred needle in the third frame spans the range of 80 to

100 PSIG. It would seem that the upper end of this range, 100 PSIG,

would be the maximum pressure during the exposure for that frame. Since

the camera's shutter is not open for the entire time length of the

frame it is likely that the actual peak pressure was missed. In

addition, this particular gauge

reads 10~15 PSIG low compared to the regulator gauge on my shop

compressor. It seems likely then that the actual peak pressure in the

chamber is perhaps 10 to 15 PSI greater than what is shown in the video.

Using the video, which is a bit sharper than the still images,

I have estimated the gauge readings as a function of time. The times

and pressures are shown in the table below.

| Frame # |

Time (Sec) |

Gauge Reading (PSIG) |

Frame # |

Time (Sec) |

Gauge Reading (PSIG) |

|

| 1 | 0 | 8 | 17 | 0.533 | 20 | |

| 2 | 0.033 | 8 | 18 | 0.567 | 19 | |

| 3 | 0.067 | 94 | 19 | 0.600 | 17 | |

| 4 | 0.100 | 76 | 20 | 0.633 | 16 | |

| 5 | 0.133 | 62 | 21 | 0.667 | 15 | |

| 6 | 0.167 | 52 | 22 | 0.700 | 14 | |

| 7 | 0.200 | 46 | 23 | 0.733 | 13 | |

| 8 | 0.233 | 41 | 24 | 0.767 | 12 | |

| 9 | 0.267 | 36 | 25 | 0.800 | 11 | |

| 10 | 0.300 | 34 | 26 | 0.833 | 10 | |

| 11 | 0.333 | 32 | 27 | 0.867 | 9 | |

| 12 | 0.367 | 28 | 28 | 0.900 | 8 | |

| 13 | 0.400 | 27 | 29 | 0.933 | 8 | |

| 14 | 0.433 | 25 | 30 | 0.967 | 8 | |

| 15 | 0.467 | 23 | 31 | 1.000 | 8 | |

| 16 | 0.500 | 21 | 32 | 1.033 | 8 |

The graph below shows a plot of this data. The red data points were

not used in the curve fits.

From this data I get a pressure

half-life

of 129mSec. This agrees reasonably well with the 110-114 mSec half-life

obtained from the acoustic studies.

Looking at the graph of the pressure versus time you notice a

systematic trend in the errors between the data points and the curve

fit line. It appears that there may be two processes going on. The

initial rate of heat loss appears to have a half-life of about 130

mSec. As the pressure drops the rate drops as well and towards the end

the rate of heat loss has dropped to a half-life of about 300 mSec. It

is possible that this trend is simply caused by the inability of the

gauge, or the video, to respond quickly enough to the initial high rate

of pressure change. Alternatively, this may represent a real

characteristic of the heat loss in this system.

GasEq indicates that the thermal conductivity of the combustion

gases at the adiabatic flame temperature is 0.15 W/m/K. Air at 25C has

a thermal conductivity of about 0.023 W/m/K. As the gases in the

chamber cool to room temperature the thermal conductivity drops by a

factor of 6.5. It is possible that the systematic trend in the pressure

versus time graph is caused by the increasing insulation properties of

the combustion gases as they cool off. PVC has a thermal conductivity

of about 0.19 W/m/K, similar to the thermal conductivity of the gases

at the adiabatic flame temperature.

Using the thermodynamic properties of PVC and the combustion gases

we can estimate the net temperature rise of the PVC chamber.

The final temperature of the chamber and gases (TF) can

be calculated from;

(Tg - TF)(Cg) = (TF - Tc)(Cc)

TF = (TcCc

+ TgCg)

/ (Cg + Cc) (Eq. 4)

The various values for equation 4 are given in the table below.

| Chamber | Value |

Unit |

Variable |

|

| Starting chamber temperature | = |

10 |

C |

Tc |

| Mass of 12" of 3"ID PVC |

= |

675 |

g |

|

| Estimate of the

mass of the chamber including fittings |

= |

800 |

g |

|

| Specific heat capacity PVC | = |

0.25 |

cal/g/C |

|

| (mass PVC) x (specific

heat capacity PVC) |

= |

200 |

cal/C |

Cc |

| Combustion Gases |

||||

| Starting temperature of gases (GasEq) | = |

2358 |

C |

Tg |

| Volume of chamber |

= |

1.74 |

L |

|

| Density of the combustion products (GasEq) | = |

1.268 |

g/L |

|

| Mass of combustion

products |

= |

2.21 |

g |

|

| Specific heat capacity

combustion products (Cv, GasEq) |

= |

0.285 |

cal/g/C |

|

| (mass gases) x (specific heat capacity gases) | = |

0.63 |

cal/C |

Cg |

| Chamber

to Gases Heat Capacity Ratio |

||||

| (mass

PVC) x (specific heat capacity PVC) -------------------------------------------------------------------- (mass gases) x (specific heat capacity gases) |

= |

318 |

|

So, for every 318°C drop in the gases' temperature the PVC

chamber's temperature rises by just 1°C.

Using the values in the table above and equation 4 we can calculate

the final temperature of the PVC and gases.

| Final

Temperature |

||||

| Final temperature of

gases and PVC |

= |

17.4 |

C |

TF |

| Temperature rise of

the PVC |

= |

7.4 |

C | |

So, even though the combustion gases' peak temperature is more than 2300C (~4200F), the final temperature of the gases and the PVC is only about 7.4C (13F) above the starting temperature.